METAL WORKS

DIVISION: 1 CERTIFIED TO CSA W47.1 & W186

As a Division 1 CWB certified company we have met the Canadian Welding Bureau’s highest standard for welding operations by employing an in-house Certified Welding Engineer. This means we maintain rigorous oversight of every weld, ensuring all procedures meet or exceed industry-leading standards. This provides clear benefits to our clients: it significantly reduces rework, streamlines project timelines, and helps prevent costly schedule delays. With tighter, on-site engineering oversight and a commitment to best practices, every stage of the welding process—from initial design to final inspection—runs smoother.

3-D SCANNING

3D scanning offers a fast, accurate, and cost-effective way to capture as-built building conditions, resulting in precise, high-resolution data that can be easily integrated into design and fabrication workflows. By reducing the need for manual measurements and dramatically reducing the potential for human error, scanning streamlines the process of creating 3D models for structural steel fabrication. This accuracy ensures that steel components are fabricated to the exact dimensions of the existing building, minimizing costly rework, accelerating installation, and enhancing overall project efficiency.

OUR SPECIALTIES

BUILDING REPAIR

Our company specializes in structural steel building repairs, delivering industry-leading solutions that address the full spectrum of challenges posed by corrosion, fatigue, and accidental damage. Although structural steel boasts excellent strength-to-weight properties and plays a critical role in our society’s building stock, it can deteriorate over time. Restoring these systems in occupied facilities requires careful coordination and adherence to stringent safety protocols—ensuring the wellbeing of both the structure and its occupants throughout the process.

We recognize the unique pressures that Owners, Consultants, and General Contractors face in the Building Restoration Industry, particularly when it comes to tight schedules, diverse stakeholder interests, and maintaining uninterrupted operations. Leveraging our extensive experience and specialized expertise, we devise tailored repair strategies that align with project needs while minimizing disruptions. Our goal is to complete repairs efficiently and effectively, preserving the building’s long-term integrity and instilling confidence in our clients that their project is in capable hands.

REBAR WELDING (CSA W186)

We offer comprehensive rebar welding services under our CSA W186 certification. Our expertise covers a range of techniques, including direct and indirect butt splices, lap splices, and fillet welds, all executed in strict conformance to Enable engineered welding procedures.

With a certified and highly experienced team, we focus on delivering reliable, code-compliant welds that strengthen your projects without compromising integrity. From initial planning to final inspection, we work with project stakeholders to achieve consistent, dependable welds for every project.

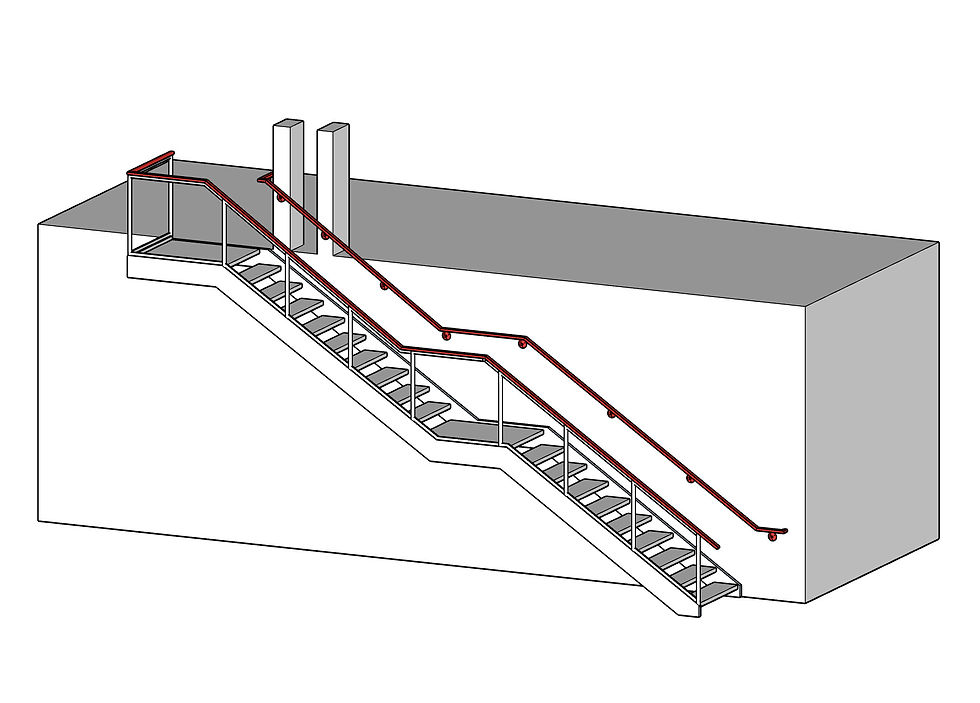

RETROFIT / FIT-OUT

Our team understands the unique challenges that arise with retrofit and fit-out projects—ranging from working with older structural elements and tighter working conditions to coordinating around existing MEP systems and the need for limited impact on building operations.

To meet the diverse requirements of these projects, we leverage a variety of welding processes—such as SMAW (Stick), GMAW (MIG), FCAW (Flux-Cored), and GTAW (TIG)—adapting our approach to suit the materials, site conditions, and project scope. This versatility not only guarantees quality, code-compliant welds but also allows us to adjust on the fly if unexpected challenges arise, keeping the project on track and maintaining the highest level of craftsmanship.

.png)